Lan-ringer® – a stretch wrap solution for heavy, odd-shaped, or high-wrap-force loads

Aug. 7, 2008

Related To: Lantech

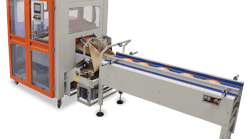

The newest model of Lantech's Lan-ringer® system proves that, when it comes to packaging heavy, unstable loads, or loads that need protection from dust and the elements, stretch wrapping is the best way to ship, regardless of the shape. The Lan-ringer provides greater flexibility and better protection for a variety of loads including windows and doors, printed materials and other items that will not fit on a turntable stretch wrapper – such as ladders, beams, vinyl siding, PVC pipe, metal fabrications and furniture. The newest model of the Lan-ringer will be demonstrated at Pack Expo in Lantech's booth No. 3604. "The Lan-ringer system is a material-saving option for packaging items such as windows and doors, because use of stretch film reduces the need for expensive corrugated packaging, and it provides the added benefit of easy product identification through the clear film," said Derek Jones, Lantech Product Manager. For packaging printed materials, the Lan-ringer can be paired with a Lantech S-Series™ machine to provide a six-sided "protective cocoon" of stretch film, keeping out dust and moisture and virtually eliminating load damage that can occur with metal banding or strapping. The Lan-ringer packaging system is an overwrap machine designed to wrap product that is moved through the production process on a conveyor. The film delivery system is mounted on a 40-, 60-, 75- or 90-inch ring through which the product passes, and Lantech's patented Power-Thru® conveyor permits wrapping of the product and conveyor simultaneously. The conveyor supports the product through the wrap zone, allowing the stretch film to be applied with the proper containment force. Product stability is maintained by wrapping the product and conveyor together. Stabilizers support the top and sides of the product and guide it through the wrap zone during the wrapping process. Loads of up to 4000 lbs. can be wrapped while the product is moving (spiral wrap mode) or stationary (banding mode) on the conveyor. After the product has been wrapped, a cut-and-clamp device cuts the end of the film, and the stretch film recovers against the product as it exits the machine. Wrapping parameters, including conveyor speed and number of wraps, are adjustable from a central PLC control, allowing loads of random length, width or height to be wrapped on one machine. There are four models of the Lan-ringer based on ring size: the LR-4000 (40-inch ring, 32-inch max load diagonal), the LR-6000 (60-inch ring, 52-inch max load diagonal), the LR-7500 (75-inch ring, 67-inch max load diagonal) and the LR-9000 (90-inch ring, 82-inch max load diagonal). Built to exceptionally rugged standards, the Lan-ringer uses a fully supported ring – not cantilevered – and a five-inch thick, precision steel bearing to ensure accurate alignment, smooth operation in adverse conditions and lowest maintenance. The machine's Power Roller-Stretch® film delivery system can utilize 20- or 30-inch film rolls. Film break detection is standard on all Lan-ringer machines. The Lan-ringer includes a Lan-Logix™ state-of-the-art control system, a Lenze 5-hp, "all in one" drive (motor, brake, reducer) and an Allen Bradley touch-screen Panel View 600 Plus. Conveyer options include drag chain, powered roller and belt conveyor.