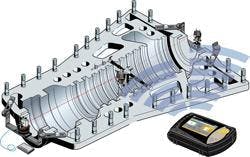

CENTRALIGN ULTRA was specifically developed for the alignment of steam and gas turbines. The system precisely aligns internal elements with upper halves installed or off, for distances up to 133 feet. Accurate bore measurements can be acquired without interrupting other work taking place in the turbine; saving time over traditional methods like piano wires, micrometers and optical instruments. CENTRALIGN ULTRA assures true bore center measurement and reveals bore out of roundness. Stable wireless data transmission ensures reliable and complete data transfer of information between the measuring sensors and the computer. Over long distances and extended measurement periods laser stability is subject to fluctuations through variations in air density or temperature. To ensure measurement accuracy, an additional fixed sensor constantly monitors the laser drift at the far end of the machine and automatically adjusts readings to compensate for such drift. The CENTRALIGN ULTRA brackets are specifically designed for ease of use and extremely high accuracy. Brackets can be installed in magnetic or non-magnetic bores, and tops-on or tops-off configurations, with bore diameters from 4.75” to 166.5”.