On-Demand Protective Wrapping System and Materials

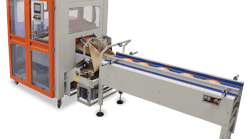

Automated Packaging Systems has introduced a new protective wrapping system that produces cellular cushioning wrap and air-filled tubes on demand. This portable, benchtop unit reduces storage costs for large, bulky rolls of pre-filled protective wrapping material by producing the material as needed at the packing station where it is used.

The new AirPouch® FastWrap™ system uses high-yield boxes of flat, preformed bubble material. When inflated at the station, these compact boxes of material produce 1385 linear feet of cellular cushioning wrap; roughly equivalent to 5½ rolls of bundled bubble product. A patent-pending honeycomb pattern allows air transfer between cells for maximum product protection. The FastWrap system is also capable of producing full-length tubes to accommodate a variety of protective packaging applications.

Several types of FastWrap materials are available. DuraClear™ LLDPE is available in both 1.5 mil standard polyethylene for most applications, as well as in green-tinted EarthAware™ LLDPE biodegradable blend. A premium grade 1.5 mil co-extruded material provides greater air retention for longer-term distribution cycles and comes standard as an EarthAware biodegradable, green tinted material.

The FastWrap system produces its cellular cushioning wrap in 12 inch widths and a continuous length with EZ-Tear™ perforations every 10 inches, making it convenient for packers to tear off just what they need for fast, efficient packing. The unique quilted pattern is ideal for interleaving and cross-wrapping. FastWrap tubes are available in 14” lengths and are 1¼” diameter inflated.

The FastWrap unit is compact, lightweight and mobile, making it one of the most flexible systems on the market. The unit is quiet and features an all-electric design that operates in semi-automatic or manual modes at a speed of 55 feet per minute. When in semi-automatic mode, an optional winder controls the system, stopping the unit when the winder spool is full. In manual mode, the system can be set to run for a pre-determined time, dropping the filled bubbles or tubes into a Gaylord or cart. An innovative engineering design has eliminated the cutting knife other manufacturers use to slit the film just prior to filling the product with air, which eliminates the main wear item found on every other machine in its class.

“The FastWrap system and materials work together to save companies money,” explains Chris Rempe, Senior Product Manager. “Shipping costs are dramatically reduced over alternative protective packing products. By eliminating the need to ship bulky, large volume materials, transportation emissions are reduced, making it a more environmentally responsible solution. The on-demand functionality of the FastWrap means companies no longer have to store or handle huge bags of EPS peanuts, bundles of pre-filled bubbles, or paper packing, allowing for more efficient use of warehouse space,” Rempe adds.

- produces cellular cushioning wrap and air-filled tubes on demand

- portable, benchtop unit

- quiet and features an all-electric design