A cold-applied splice provides both wire termination and environmental sealing in a single step. Sealing is provided without the need for adhesives, tapes, grommets or other methods traditionally used in aerospace and defense applications. Because no heat is needed, the splice can be applied in potentially hazardous places, such as in fueled aircraft.

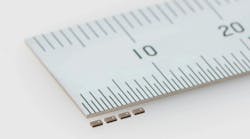

The one-piece construction not only simplifies use, but it also allows a compact space-saving profile. The immersible splice prevents water from entering even under permanent pressure or weight. The splice uses a non-flowing gel to provide excellent sealing without the mess. The metal splice is tin-plated copper with a transparent polyvinylidene fluoride sleeve and color-coded thermoplastic end caps.

The splices are available in three color-coded sizes for 26 AWG to 12 AWG wire with silver or copper-plate conductors. They are rated for operation from -65 to +150°C. They meet the requirements of SAE-AMS-DTL-23053/8 for insulation sleeve and the current draft of SAE-AS81824/12 (modified for 150°C) crimp splices.