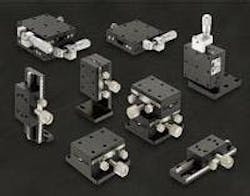

Standard Precision Positioning Stages

April 16, 2011

Related To:

MISUMI USA recently announced the addition of several new products to its family of Standard Precision Positioning Stages. These versatile devices are designed to meet a wide and diverse range of positioning application requirements. When compared with conventional high precision positioning stages, either purchased or produced in-house, the Standard Precision Positioning Stages offer excellent value – delivering a cost savings of 20 to 45 percent. All styles are shipped in three days. Standard Precision Positioning Stages are used by industrial companies to perform various positioning tasks in tooling jigs, manufacturing, assembly, testing and inspection, nesting, and sensor adjustment. Now with 22 different styles available in MISUMI’s 2011 lineup, users can select from among a broad range of products, depending on specific application requirements such as: moving axes, positioning accuracy, load capacity, feed mechanism (rapid or fine), linear guidance structure (Dovetail, Cross Roller, or Linear Balls), and type of clamping mechanism. All of MISUMI’s Standard Precision Positioning Stages are quickly and easily adjustable without the use of tools. Their simple, compact design and rugged construction provides long-term reliability, as well as ease of alignment and positioning repeatability.