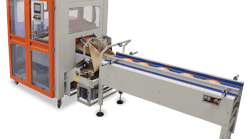

Lantech's Q-300XT stretch wrapping machine improves operator friendliness with a larger load-placement window for its automatic film cut-and-clamp system. Designed to eliminate fork-driver dismounts, the patented XT film cut-and-clamp system features space-age composite parts and allows a generous 10-inch offset for most loads, while providing automatic attachment ofthe film to the load and cutting of the film upon completion of the wrap cycle. The fully guarded cut/clamp system flips up for easy cleaning. The new-design cut/clamp module is standard on all XT equipped Lantech machines, and a retrofit kit for existing machines with the XT cut and clamp modulewill be available for select models.The Q-300XT stretch wrapper allows the fork truck operator to simply drive up, position the palleton the turntable, start the machine with a lanyard switch or a wireless Click-n-Go™ remote, and driveaway – without ever getting off the fork truck. Simple Automation™ of the Q-300XT reduces wearand tear on fork truck operators and equipment. The higher efficiency can free up fork trucks for otheruses or possibly eliminate some equipment and the associated operating costs.The Q-300XT wraps loads up to 80" (2 m) tall and weighing up to 4000 lb (1814 kg). Themachine's electronically controlled, variable wrap force and 200% pre-stretch on the film ensureconsistent, tight loads with economical use of film, reduced labor and improved ergonomics. Filmpre-stretch up to 300% is available. The stretch wrapper is easy to operate with a touch panelcontrol, featuring color-coded operating functions for quick, clear identification. And, the entire systemis backed by a full three-year, unlimited-cycle, all-component warranty.

- 10-inch offset for most loads

- eliminate fork-driver dismounts

- patented XT film cut-and-clamp system