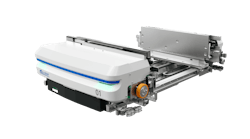

The new Megamat RS Vertical Carousel features a new intelligent drive design, providing industrial product operations a more reliable vertical carousel requiring less maintenance and lower energy requirements. The new intelligent drive design is made up of a drive track, carrier arms, transportation chain, drive motor, drive chain and hand crank. Working together these components reduce the wear and tear on the unit and require less energy to move the carriers around.

In other standard vertical carousels, the motor is mounted to a fixed location. As weight is added or removed from a carrier the drive chain loosens or tightens requiring frequent adjustments and maintenance. The Megamat RS Vertical Carousel is designed with an automatic chain tensioner system. The drive chain is automatically tensioned using the weight of the motor, eliminating the need for frequent chain retentioning that is common with other vertical carousels. The motor and drive chain are mounted as one assembly onto a drive bracket that allows the complete assemble to slide up and down to automatically adjust in relationship to the weight of the carriers. As the carrier weight changes, the entire assembly moves eliminating the chain loosening or tightening that requires frequent maintenance.

With an intelligently redesigned track and carrier arm system, the Megamat RS Vertical Carousel has reduced the number of parts and materials required. This creates a lighter load for the motor to push around the track and reduces the amount of energy required to drive the unit.

In an emergency, such as a power outage or if several electrical components break down simultaneously; a plug-in crank handle can be used to access the desired carrier. The emergency crank handle option is not a long-term alternative drive solution but does allow safe temporary access to stored goods in the event of a power outage.

- new intelligent drive design

- automatic chain tensioner system