FP International is proud to announce their new PILLOW PAK® Anti-Static Air Cushion Film – with superior product protection that is the first of its kind that can be made-on-site. FP International is a global leader in providing interior packaging solutions systems used in demanding applications for retail, electronics, medical, aerospace, health and beauty, auto and other packaging markets. The new PILLOW PAK Anti-Static Film blend technology meets or exceeds the Electrostatic Discharge (ESD) performance criteria of these three established standards, at the time of manufacturing: EIA-541, MIL-PRF-81705E, and the PPP-C-795D Class 2. These standards have two major ESD criteria: Static decay: Less than two seconds Surface resistivity: Equal to or greater than 1.0 x 105 ohms/sq. but less than 1x1012 ohms/sq.

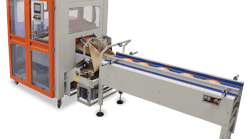

Michael Kaminski, Senior V.P. Worldwide Engineering & R&D at FP International says, “In this time of minimizing storage space, and reducing costs and quantities of packaging materials on-hand, the PILLOW PAK Anti-Static bubble offers our customer base ‘just-in-time’ ESD air cushion packaging. Our military and electronics vendor base is elated with this innovative product. By meeting the ESD performance criteria, the PILLOW PAK Anti-Static Bubble is the best ESD cushioning protection for packaging any shipment.” One feature of this superior cushioning film is the ability to make it on-site, fast, at 120 lineal feet per minute.

The PILLOW PAK Anti-Static film is durable and tough, so it won’t lose its cushioning integrity during shipment and through extended storage. Another feature is the film allows air to move (or transfer) between cells to provide continuous, product cushioning and protection compare to standard bubble. One roll of PILLOW PAK Anti-Static film is 30 inches by 1,200 feet and 7/8” in height. The entire roll can be inflated in only two minutes, and one pallet of film is the equivalent of one truckload of standard bubble.

- made-on-site

- durable and tough

- continuous, product cushioning