Fiber Laser Cutting System - Miyachi Unitek Corp

Sigma XY fiber laser cutting system enables high speed precision laser cutting of thin metals using a rigid linear drive, gantry-based motion system. The perfect choice for fast cut cycle times and superior laser cutting quality, the Sigma XY fiber laser cutting system is ideal for cutting metal laminates, electronic device mounting plates, and medical cutting blades. Combining high accuracy linear motors with the fine spot capability of the LF series range of fiber lasers enables the Sigma XY to offer high dimensional accuracy on cutting profiles. A proprietary laser power ramping algorithm for acceleration and deceleration profiles provides fast cut times and consistent thermal input for stable cutting.

The fiber laser technology offers high resolution cutting, with optical spot sizes down to 10 microns, and high linear speed cutting possible through high pulse repetition rates. Up to 500W of available laser power makes the Sigma XY perfect for a wide range of materials, including steels, aluminum, and brass. Miyachi Unitek’s fully integrated laser control optimizes cutting, enabling pulse widths to 20 microseconds, pulse frequency up to 50 kHz, and precise control of the power.

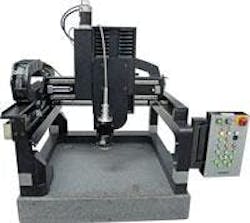

Equipped with a 4-inch thick granite base secured to a high strength welded steel base, the system offers the mechanical stiffness necessary to accommodate the high acceleration and deceleration rates that minimize cycle times. The Sigma XY is available with a variety of options, including Class 1 or Class 4 operation, several cutting box styles, fume exhaust, part hold down tooling, focus control sensing, programmable gas pressure, high pressure cutting heads, 4-inch or 8-inch travel Z-stage axes motion, and a control pendant.

- fast cut cycle times

- rigid linear drive, gantry-based motion system

- up to 500W of available laser power