Swagelok Ammonia Sampler

Oct. 27, 2023

Related To:

2023 NED Innovation Award Finalist

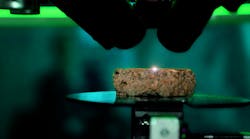

The Swagelok ammonia sampler makes sampling of anhydrous ammonia safer by minimizing operators' exposure to liquid and vaporized ammonia. It also introduces consistency into the sampling operation, expediting the sampling process, and eliminating the need to transport ammonia samples within the facility.

The ammonia sampler addresses the common challenges and issues inherent to manual sampling by using:

- Closed-sample fixtures that improve safety by limiting operator exposure and minimizing environmental impact from excess emissions

- Residue tubes that are pre-chilled using the cold ammonia itself, thus preventing aggressive boiling that threatens fill accuracy

- Features that help to control the dispensing of the ammonia sample and ensure a consistent sample size

- A single handle for easier operation and reduced operator error

- A touchscreen interface to control all heater operations

By enabling a semi-automated sample-collection process, the Swagelok ammonia sampler improves quality control oversight by providing the most accurate results possible, while also making ammonia sampling as safe and efficient as possible.

- Minimizes hazardous exposure to the operator

- Introduces consistency into the ammonia sampling operation for more accurate results

- Expedites the gathering of results

- Adheres to the highest quality and safety standards

- Closed-sample design eliminates the need for extensive operator PPE

- Glass design allows operators to visually monitor sample conditions

- Available in single- or dual-fixture designs

- Fill level of the cold bath is controlled using an elevated drain tube

- Filling the cold bath clears the supply line of older ammonia, resulting in a fresh sample

- Ammonia fast loop chills the sampling valves

- Concentric tubes prechill the sample lines

- Cap assembly seals on top of the residue tube and controls fill level

- Overflow empties into the cold bath, ensuring consistent sample size

- 100 mL or 250 mL residue tube sizes are available