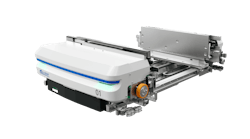

Pallet-Shuttle System

The new UltraRail™ (patent pending) LIFO pallet rail-shuttle system from Integrated Systems Design (ISD) combines the benefits of push back, drive in and shuttle systems to give organizations a cost effective way to expand capacity and improve productivity in pallet storage applications. The UltraRail system eliminates aisles and converts the end of each lane into an active storage and retrieval position. Each lane can hold up to 10 positions or more. It offers 100% increased selectivity over drive in systems. It can double pallet storage capacity or eliminate up to 50% of existing floor space requirements, and can improve productivity up to 75%.

The UltraRail system uses mechanical force, not gravity, to move pallets in or out on rails. After the first pallet is loaded, the second loaded pallet pushes back on the first, turning the UltraRail chains. When the pallets are removed, the chains move in the opposite direction. The lift truck lifts the front pallet, and as its backs up, the weight of the pallet being removed moves the chains. When the front pallet is removed from the system, other pallets in the lane automatically move forward on the chain, positioned for sequential retrieval. The UltraRail pallet rail-shuttle system can be installed on new or existing pallet rack and drive in systems and can be expanded, shortened or moved. Typical applications include high bay storage, pallet picking, buffering and sequencing, and truck loading and staging.

- expand capacity

- each lane can hold up to 10 positions or more