Liquidtight Fittings

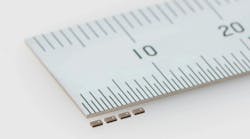

The innovative push-in design of the new Thomas & Betts (T&B) Quick-Connect™ Liquidtight Fittings reduces installation from six steps to two easy steps, making installation onto liquidtight flexible metal conduit faster and easier. “This new design improves efficiency and reduces labor costs,” said Chad Smith, global product group manager at T&B. “The installer now only needs to push the conduit into the fitting and tighten the gland nut. No disassembly is required.” Quick-Connect™ Liquidtight Fittings feature captive sealing rings available from 3/8 inch to 1 inch, in straight, 45-degree and 90-degree configurations.

The Quick-Connect™ Liquidtight Fitting installs up to three times faster than standard liquidtight fittings. The two-step process simplifies fitting installations to flexible conduit, while providing the high performance that liquidtight applications demand. In addition to reducing installation time, the simplicity of installing Quick-Connect™ Liquidtight Fittings reduces the likelihood of components being dropped, lost or damaged during installation. Designed to protect electrical systems from liquid ingress, corrosion and extreme temperatures, the T&B liquidtight series of fittings is ideal for food and beverage processing, wastewater treatment, panel building, chemical processing, railroad, industrial maintenance, repair and operation (MRO), and manufacturing applications.

- installs up to three times faster