Three Reasons to Avoid Horizontal Hose Ports

Smart-Hose Technologies is an engineering company and are considered to be hose experts. Many times throughout the year end users will request information regarding the mean time between failures for their hose applications. It is important to note that the mean times between failures for all hose assemblies are directly related to the application and how the hose assembly is being used.

Hose port configurations represent a critical component regarding how much stress the hose assembly experiences during day to day loading / unloading operations. If the hose assembly experiences an excessive amount of stress, the mean time between failures will be decreased. Horizontal hose ports can create an excessive amount of stress on the hose assembly which can lead to three key safety issues.

Horizontal Ports Can Impact Safety

1. Pull-away Incident: If the horizontal port hose assembly is involved in a pull-away incident, the probability is high that it will be a straight line pull. Typically, the pull-away forces associated with a straight line pull-away will be extremely high. For example, a 2-in. textile braided hose assembly in a straight line pull-away can experience 12,000+ lb. of pull force before it fails. Under those circumstances the hose assembly may no longer be the weak-link and can damage plant piping, bulk-heads, tank truck piping and loading arms before it fails, which can lead to an uncontrolled release of a hazardous material.

2. Accidental Release: if the facility experiences an accidental release from a horizontal port, the hazardous material could potentially discharge directly at the operator, hitting them in the chest or face, which can lead to an injury or even death.

3. Excessive Hose Stress: Finally, horizontal hose ports significantly increase the amount of stress on the hose assembly. A horizontal port configuration will concentrate the weight of the hose and the weight of the material being transferred through the hose assembly on the back of the barb of the end fitting. The conveyance of product vibration, combined with the concentrated stress on the back of the fitting barb can create a swing effect on the hose tube. The additional stress on the hose assembly can lead to premature hose failure and significantly shorten the functional life of the hose assembly.

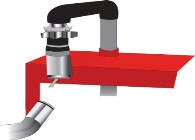

45 Degree Hose Port 90 Degree Hose Port

Whenever possible, Smart-Hose Technologies recommends a 45 or 90-deg. hose port for critical transfer applications. If the facility experiences an accidental release while operating one of these hose ports, the hazardous material released will be directed towards the ground and not directly at the operator. A 45 or 90-deg. hose port removes most of the stress off of the back of the barb of the end fitting and will therefore extend the functional service life of the hose assembly. Finally, the pull force / break force associated with a hose assembly attached to a 45 or 90-deg. hose port will be significantly less.