In manufacturing, a smart and straightforward system is changing the production and packaging of products that come in various formulations like colors, scents, and flavors. New mixing systems are dramatically increasing production flexibility and operational efficiency. They're also minimizing waste, reducing labor requirements, and optimizing overall productivity and sustainability.

Walk through the aisles of any grocery store or pharmacy, and you'll encounter a staggering amount of SKUs and a plethora of choices that consumers now expect. From an array of toothpaste formulations to bottles of colorful CBD and vitamin gummies, the variability is endless.

These dynamic marketing initiatives place increasing demands on the manufacturing and packaging processes. This calls for versatility, flexible production, and adaptability, all while ensuring unwavering product quality and consistency.

Types of Inline Mixing Systems

Originally known as "color mix" systems, these methods have been commonplace in the production of paints, sealants, adhesives, and other building materials where precise coloring is crucial.

Today, advanced custom mixing systems are being adopted in the manufacturing and packaging of viscous products—such as creams, lotions, and pastes—across many industries including food, cosmetics, pharmaceuticals, and animal health.

Custom mixing systems have evolved to meet the unique needs and stringent requirements of these sectors. New enhancements include stainless steel for optimal hygiene and sanitation, servo drives for precise dosing, and flow meters for rigorous quality control and traceability.

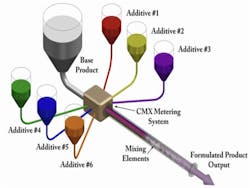

The systems are used for various additives, including pigment, catalyst, and flavoring:

- Pigmenting: One or more color dispersions or dyes can be added to the base material to create a range of shades or unique colors.

- Catalyst: A catalyst can be blended into the base material to finalize a formulation, which extends the pot life for the base product and also allows the catalyzing reaction to build viscosity after packaging.

- Flavoring: Flavors and scents can be blended into the base material to customize a formulation.

Bulk Mixing

The traditional method involves mixing the entire batch for each final product in large vats of 50, 1,000, or 3,000 gallons. Managing such large volumes presents challenges in consistently perfecting the recipe and ensuring uniform blending, especially with highly viscous products. Once a production run is completed, the vat and the entire system—including all lines from the vat to the filling nozzles—require thorough cleaning, which demands extensive manual labor and leads to considerable waste of unused product.

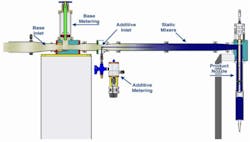

Custom Inline Mixing

On-demand, inline mixing is simpler, more efficient, and less wasteful. Additives are injected near the point of use, just before filling. Servo-based injection of additives is significantly more precise than mixing large volumes in vats. Changeover to different product formulations is much faster, easier, and less wasteful.

These systems offer several benefits:

- More Accurate: Mixing small amounts is more accurate with servo-driven, automatic injection, ensuring high repeatability and precision.

- Less Cleaning: Traditional methods require cleaning the entire system, which can take hours to days. In contrast, custom mixing systems require cleaning of only 12 to 36 inches of tubing, depending on the number of additives. With an extra set of tubing on hand, changeovers to a new formulation can be performed in as little as 3 to 5 minutes.

- Less Waste: Inline mixing at the point of use generates minimal waste during changeovers. There's no need to dispose of the unused product and residue from vats and production lines, reducing waste to about a half gallon.

- Less Time: Faster changeovers occur in minutes rather than the hours or days required for cleaning vats and entire systems. This enables "just in time" production and enhances productivity — saving 500 to 1,000 hours annually otherwise spent on cleaning.

- Less Space: Custom mixing systems easily integrate with any filling system. They can be portable, making it possible to roll them to different filling stations as needed. The space savings are significant as fewer large vats are required, and the efficient changeover supports a more streamlined manufacturing and packaging process, reducing inventory requirements.

Custom mixing systems offer significant advantages over traditional methods, particularly in precision, efficiency, and waste reduction. These systems enhance accuracy by allowing for the precise mixing of small amounts, leading to consistent product quality. The ability to quickly switch between different formulations with minimal cleaning drastically reduces downtime, enhancing productivity by saving hundreds of hours annually.

Moreover, custom mixing systems generate less waste, minimize required storage space, and offer greater flexibility due to their portability. These benefits collectively contribute to a more efficient, sustainable, and cost-effective manufacturing process, making custom mixing systems an invaluable asset for modern production environments.

About the Author

Jack Johnson

Senior Application Sales Engineer, ProSys Fill, LLC

Jack Johnson is the Senior Application Sales Engineer at ProSys Fill, LLC. He is approaching 40 years in the engineering field. From drafting, product design, project management, and application sales for custom machinery. He has spent 25 years in container-filling product design and application sales.