Are you as impatient as me for this future everyone always talks about? You know, the one where every device and machine is connected to better serve humanity, where robots do all the monotonous and dangerous jobs while you live out your fantasies in virtual reality, and anything and everything you need—from replacement parts for your robot slave to a new liver—can be 3D printed and delivered to you by drone?

These are all real goals from real technology experts, and if technology continues to grow exponentially—as Moore’s Law states—we’re closer to this Philip K. Dick fantasy world than the era without iPhones, announced exactly one decade ago.

One of the major keys to unlocking this high-tech utopia/dystopia made its first appearance this month at the 50th Consumer Electronics Show in Las Vegas: the Artec Leo 3D scanner.

With Leo’s 60 frames per second rate, the Luxembourg-based Artec 3D can currently claim that the Leo is one of the fastest 3D scanners ever made.

The faster you can scan, the more you can scan. The more you can scan, the faster everything has a digital copy. From there, who really knows?

From a manufacturing standpoint, metrology, reverse-engineering, rapid prototyping, quality assurance, and design applications all use 3D scanning now. Non-industrial uses include medical and forensic applications.

“Given Leo’s high fps rate, you get more reliable tracking,” says Andrei Vakulenko, Artec’s chief business development officer, and point of contact at the CES Booth in the Sands Expo & Convention Center. “You don’t need to think if your movements are smooth enough to capture the surface. You scan faster.”

Speed makes this scanner an intriguing tool, but hardly a catalyst for the impending technological singularity. What makes this industrial scanner truly innovative, and comparable to the iPhone in terms of disruption, is that this wireless 4-lb device can be used anywhere, and makes any user feel like an expert.

“While 3D scanning still requires some skill, we make our scanners as easy to use as cameras,” Vakulenko says.

A built-in battery and wireless connectivity aren’t the only thing that makes this mobile. Artec installed a NVIDIA Tegra mobile platform, which includes embedded FPGA, quad-core CPU, and 1-teraflop GPU processors, along with a 5.5-in. touchscreen, making Leo the first scanner to allow automatic 3D processing onboard.

Visit www.Artec3D.com for more information on their line of 3D Scanners.

In simple terms, you see exactly what your 3D model looks like as it’s being scanned. You need only to look at the screen on the back, like a 3D version of a digital camera.

“With Leo, you don’t need any tablets or laptops to scan,” Vakulenko says. “You can freely walk around the object you’re scanning, and thanks to the scanner’s built-in half HD screen you can see scan data collected in real time right in front of your eyes.”

Even Artec’s popular Eva—a beloved tool for 3D modelers and printers in fields varying from archaeology to Hollywood special effects— looks absolutely primitive to the new king of the 3D jungle. Whether it’s a metrological task in a casting foundry or capturing fossils at an African dig site, the Eva requires a rather cumbersome configuration of power supply, laptop, and scanner, all tethered together by a tangle of wires.

For small objects, this really isn’t that much of a problem. But if you’re walking around a car, for instance, that configuration is not just annoying; it’s sometimes a safety issue.

“In some industries it’s dangerous to be scanning and having to do too many things, like in aerospace,” says Vakulenko.

Photo: Artec

A New Breed

CES wasn’t the first time Bruce Glenn, V.P. of new technologies for equipment distributor ScanSource, learned about Leo. He has already had a lot of experience selling Eva, and says ScanSource has “a bunch of Leo’s on order” for their network.

At CES 2017, Glenn checked out the Leo on display, along with the body scanner and a Space Spider attached to a robotic arm.

“I really think that a lot of the applications for scanning, for big applications, have not been realized,” he says, waxing about how people have lined up to get scanned and have a figurine created.

The issue, he says, comes down to education. As a large scale seller, it’s his job to preach the merits of these high-priced tools to resellers. With Eva, he says that hasn’t been difficult, as customer reaction for that model has been “overwhelmingly positive.”

And for about $6,000 more, they can get a Leo, which exceeds Eva in nearly every category.

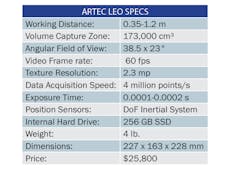

According to Artec, Leo captures frames four times faster (60 vs 16 fps) and doubles the data acquisition speed to 4 million points/s. The texture resolution has been increased to 2.3 mp, compared to Eva’s 1.3 mp. For engineers working on large pieces, architecture, and aerospace applications, the stat that jumps out is the field of view six times larger than Eva’s. The volume capture zone is 173,000 cm³.

“You know normally you got to get pretty doggone close scan something,” Glenn says, “but this means you can walk around a car, a bus. The field of view is gigantic.”

Other key features include the embedded 9 DoF inertial system, which comprises an accelerometer, gyro, and compass, also informs the scanner of its exact position, and the advanced VCSEL light sources that allows the scanner to adapt to a wider range of lighting conditions. Using 3D HDR, it can even capture black and shiny objects.

Unlike some other high end scanners, you don’t need to put trackers on the object you want scanned. Using advanced hybrid geometry and texture tracking, the user points and shoots. If you think of how difficult it used to be to take clear pictures before digital camera and autofocus works, you’re on the right track.

This, Glenn says, opens up much more of the world to 3D scanning.

“It will give us the ability to get into places you couldn’t get into before,” he says. “We think that we’re going to be able to get into more applications, particularly in fields where people are mobile. You need to go out and scan something, you just bring it. It’s going to open up applications where it’s difficult to scan stuff, like walking around inside of an airplane wing, climbing around a structure.”

Super Modeling

When Johannes Gutenberg invented his printing press, he didn’t invent books. He made books more accessible by speeding up the process of copying pages. And that innovation led to a rapid spread of information, and eventually the Renaissance. It was a bridge between people and information.

When the iPhone was released, it combined a phone, camera, video camera, radio, navigation tool, and the Internet in one handheld device. Then developers democratized the device and found a million other uses for it.

This scanner represents the first of a new line of 3D scanners that will also make 3D modeling more accessible.

Glenn believes it is also something never before seen.

“We’re into a brand new category of products,” Glenn says. “Uber is a new category of driving and picking up people; the Leo is a new category of portable scanner that no one has put out. All that they learned on their first platform with the EVA and the [Space] Spider, they’ve taken the best of that and created an even better platform that’s going to be the basis of a good generation of scanners.”

A new generation of scanner is really just was needed, because the new generation of engineers is wired differently. Younger engineers have been conditioned to capture visual data by looking directly at it. Millennials chronicle their whole lives by pointing a screen at things they want to post on their Instagram or Facebook or Snapchat.

And this generation is used to intuitive software, tools that know what they want, so they can spend more time creating. If you have to spend all your time learning how to use the equipment, you aren’t spending any time using the equipment.

This leads to one of the main issues Artec identified with 3D scanning is that it can take several months to train someone to use the equipment. With Leo, you will need training, but not nearly the level of previous iterations.

“We have reduced the time frames needed to learn how to 3D scan,” Vakulenko asserts. “You don’t have to keep the same distance from the object you’re scanning. Due to the scanner’s larger field of view, you can make a scan of the whole of a large object and then move closer to get the details. The scanner is so smart it knows where the object’s top and bottom are, where you are standing, how fast you’re moving around the object.”

Post-processing, another pain point for engineers working with 3D models, has also been reduced.

“Much of the preliminary processing is performed inside the scanner, and after exporting the data to your computer you can treat the scans in a much faster manner,” Vakulenko says.

As important as the hardware is to make scanning easier, the software is just as vital.

The iPhone has iOS, the Leo will have Artec Studio 12 (expected in April), which Artec says will expand its audience and make scanning even easier. While the Leo displayed at CES was not ready to demo as the company had hoped, the Space Spider and Eva were available to users in 2016 featuring Studio 11 and the Autopilot data processing mode, and it appeared rather easy for a novice to pick up the scanner and capture 3D data.

“Autopilot is an interactive guide that asks you a few simple questions to automatically build the 3D model you need,” Vakulenko says.

“It’s killer,” says Glenn. “They have all kinds of automated features in there, basically wizards the user can run and get their scanned data processed very quickly automatically or they can choose to go manual and get in and diddle with it however they want.”

Capturing Possibilities

We talked to the manufacturer and a reseller, but what do end users say they need?

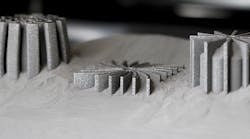

Leo is so new, no customer has even tried it, so we asked Stratasys for their take on current 3D scanning, and Adam Stegeman, senior application engineer, responded.

“It is becoming easier and more standard to get a watertight STL file as an output from the 3D scanners,” Stegeman says. Having a watertight STL is all a 3D printer requires for the print job.

He adds that manipulating these files in the past has been a challenge.

Photo: Stratasys

So what does 3D scanning innovation mean to a real engineer?

“It opens up more viable avenues for companies and individuals to get to 3D printable content,” he says. “It allows design firms to more easily reverse engineer product from the past that has no CAD data available or manufacturers to easily create nesting fixtures for parts that might not have electronic CAD data. It can also allow artists not trained in 3D modeling to be more creative with the media used in their artistic process.”

And as more people were able to take pictures, we got more cameras. Now digital cameras are embedded in every smartphone, even cheap burners. And if you’re looking for a solid digital SLR camera, you can get one for under $200. To put this in perspective, ten years ago, Popular Photography wrote this about digital cameras: “Under-$2K is still advanced-amateur territory.”

If you consider small manufacturers as the consumer in this scenario, then industrial scanners that cost $25,800 and keep up with or exceed the abilities of a $70,000 version, and requires less training, really can make a huge difference.

For Glenn and other resellers, this could be one of the few downsides, as their margins will also drop.

“It’s too good of a deal, Glenn says. “I think it’s worth more than they are asking for it.”

And Leo is Artec’s first of what they expect to be the first of a new generation of scanners. It’s possible that the all-in-one brains could be dumbed down a bit for a new version of Eva or Eva Lite, the $9,800 entry level scanner that has only geometry tracking and capture.

“It’s really amazing technology, and it’s there and it’s looking for bright people to go, ‘You know what, with that I can do this; I never imagined that could happen before,’” Glenn says.

— with additional reporting from Travis Hessman