It's difficult to imagine a single manufacturing company that is immune from the worker shortage plaguing the industry.

Manufacturing is facing a perfect storm of potentially disastrous conditions: an aging workforce on the verge of retirement, a lack of skills and experience in the market, and a general lack of interest among young workers to enter the industry at all.

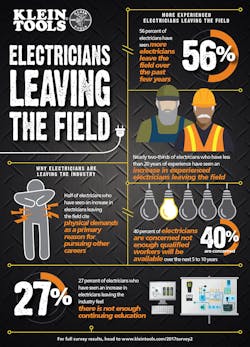

In this light, the results of Klein Tools' 2017 "State of the Industry" survey of electricians shouldn't come as a surprise to anyone.

Of the 600 union and non-union workers polled in the study, 56% say they have noticed more experienced electricians leaving the field over the last few years—a 12% jump from 2015's results.

And then there's the skills issue: 40% of the electricians reported concerns that there will not be enough qualified workers to maintain the industry in the next 5-10 years.

While concerning, these numbers aren't a revelation; it's the same story reported across the manufacturing world every day.

However, when we dig a little deeper into the study, we find a couple of significant surprises.

First, half of the electricians in the survey who reported an increase in vacancies list the physical demands of the job as the primary reason for their brethren's departures.

Then, 27% of those same workers note concern that the lack of continuing education is pushing experiences electricians away—a stat Klein notes is "significantly higher" than the 2015 findings.

These two results completely change the worker shortage discussion.

In this industry, it seems, the issues aren't age and interest so much as a lack of resources. And that means this crisis, at least, is treatable.

With access to the right tools and the right training, employers can reverse this trend and empower electric workers to keep us wired and running well into the future.

As it happens, Klein Tools—which ran the study—offers both of these assets. So we connected with Greg Palese, vice president of marketing for Klein Tools to find out what they are doing and what the industry can do to turn this whole crisis around.

NED: How serious is it that electricians are leaving the profession, and what is the risk/effect for American industry?

Palese: We take the Skills Gap very seriously and we view the shortage of electricians as a critical issue.

Quite simply, it's going to be harder to find an electrician, or any skilled professional, in the next few years. The simple fact that electricians may be harder to come by may lead to more homeowners taking on projects they may not be qualified to undertake. If we cannot fill these positions with skilled workers, business and homeowners will see more delayed projects and higher income prices.

Also, the fact that there are fewer experienced electricians on the jobsite may have a detrimental effect on the ability of the American industry to keep up with demands.

As a country, we are actively discouraging young people from considering careers in the trades. We need to do a better job of challenging young people to explore the trades and communicate the benefits a skilled trade job can have on one's career, including job flexibility, potentially high wages, and pride of ownership.

Also, businesses need to take a proactive approach and invest in talent by offering internships, apprenticeship programs and summer job opportunities on the local level to provide real-world, on the-the-job experiences.

NED: How do the Klein Tools Slide Drivers and Heavy-Duty Wire Strippers help electricians stay effective and healthy? What other specific products of Klein's help?

Palese: We spend a lot of time with professional users to learn about their frustrations and pain points on the job. This allows us to develop and deliver solutions professionals truly want and need. Where others find challenges, we create solutions - for the professionals who use our tools to get the job done.

Today, electricians are seeking hand tools that have multiple functions in one tool. The ability to replace several traditional tools with one multi-function tool takes weight out of the tool pouch and eliminates time spent looking for a particular tool.

Other multi-function products include our NCVT3 and NCVT4; non-contact voltage testers with flashlight (NCVT3) and IR Thermometer (NCVT4), and even our Electrician's Pocket Knife with a #2 Phillips.

NED: Can you name three non-Klein (brand or no brand, your choice) tools, devices, ergonomics, or PPE that you would recommend electricians use to prevent injury or strain on the job and why?

Palese: Gloves (including our line of Tradesman Pro Gloves) - #1 injury on jobsite is back-related. #2 is hand related injuries. We have several different gloves that protect your hands during specific jobs, such as our Journeyman Wire Pulling Gloves.

Work at Height – OSHA ranks being "struck by an object" as the third leading cause of work disabling injuries. Safety best practices are increasingly dictating that a worker's tools have to be connected to reduce the risk of dropping.